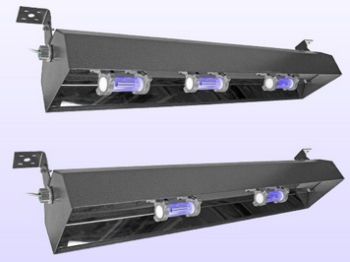

Far-UV Fixtures Safely Sanitize Occupied Areas in Your Plant

Traditional sanitation methods, such as wiping down contaminated surfaces with liquid cleaners and spraying rooms, take time to implement in occupied areas. For fast-moving operations, these slow sanitation methods could result in decreased productivity and long downtimes.

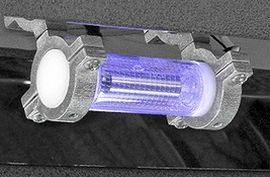

As a superior cleaning solution for busy facilities, Larson Electronics far-UV linear fixtures address the limitations of traditional sanitation methods. These far-UV excimer lamps are eye and skin safe, which allow the units to be used safely in occupied areas without protective gear.

Unlike traditional UV 254 nm disinfection lamps, the germicidal far-UV 222 nm beams generated by these lights cannot penetrate the skin and does not damage the cornea. This unique feature ensures people in occupied areas are not harmed by the fixtures, as the units continuously sanitize the room.

Other benefits of far-UV excimer lamps include:

- Ozone free

- Mercury free

- Instant on (no warm-up)

- Low heat output

The 222 nm sanitation fixtures in this series are made in the USA and come in a variety of sizes, lamp configurations, mounting styles and sensors. Customers can choose models based on the sanitation requirements of their facility.

A durable, 2-layer powder coating protects the aluminum housing of the lights from rugged elements, such as moisture and debris.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::